The English version of our website is still under construction.

Services

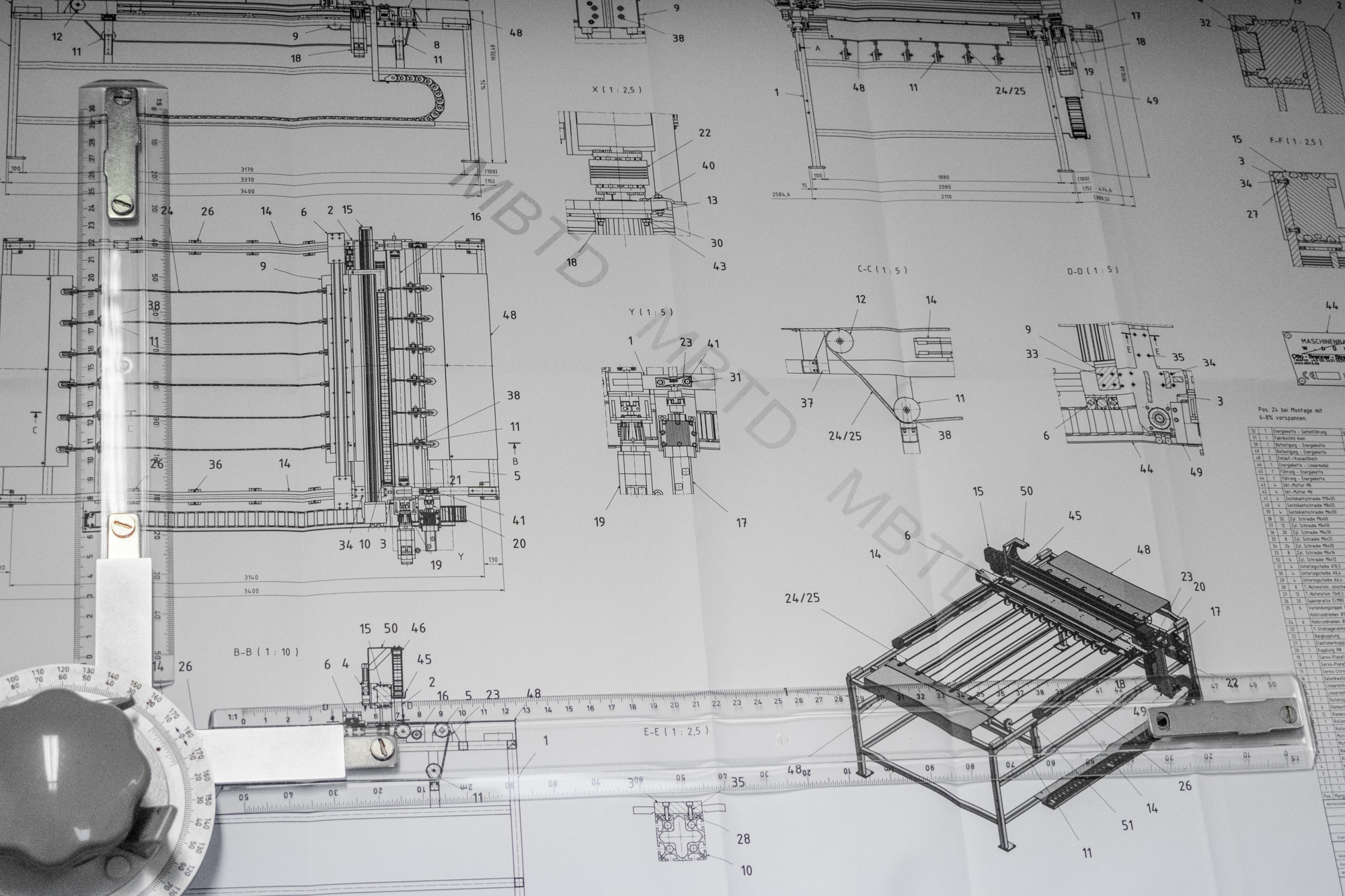

Trust in outstanding qualifications, profound expertise and 25 years of experience. As experts and consultants we support you in the fields of mechanical engineering, plant engineering, apparatus engineering, technical documentation and pressure vessel construction.

In the following you will get an overview of our main areas of expertise. We would be pleased to support you with consulting, analysis and evaluation.

Overview of our focus

- Clarification of malfunctions in machines

- Assessment of damages, their cause analysis and remedial measures

- Assessment of the structure and content in the event of damage caused by incorrect operation (technical documentation)

- Assessment of the content as well as defect findings and possibility of incorrect operation (technical documentation)

- Completion certificates according to the new law on contracts for work and services

- Evaluation of functionalities, running capabilities as well as defect findings

- Evidence procedure

- Functionality appraisal

- Valuation of equipment and systems

- Technology assessment, system analysis

- Out-of-court conciliation proceedings

- Insurance appraisals

- Court appraisals

- Private expert opinions

Repairs

Sometimes faulty operation is enough, often it is simply the passage of time – as robust and massive as most rollers are, a few years in full use leave their mark on every roller. But that doesn’t have to be a reason to think about buying a new one! The material is usually completely intact.

We specialize in restoring rollers with heavy signs of use or damage to as-new condition within a short time. We restore the surface structure of your roller and restore its optimal concentricity. Afterwards, the roller not only looks like new, it also fulfills its intended purpose again with maximum efficiency.

Services:

- Surface repairs

- Renewal of cylinder jackets

- renewal/cleaning of duct systems

- Spot welding

- Restoration of geometry (bearing seats, fits)

- Renewal of bearing journals e.g. in case of journal breakage

- Flushing of the heating/cooling system e.g. in case of heavy contamination

- Renewal of the coating (chrome, zinc, rubber, Teflon, etc.)